We had an interesting situation develop recently for a data logger that we resell. If you follow the link you’ll see that this is an inexpensive, thermocouple (TC) data logger that’s actually quite popular. This particular application needed to monitor the temperature of biological samples shipped via FedEx over a four-hour flight. The goal was to provide confirmation that the temperature of the samples didn’t dip below a given threshold before arriving at the destination. First, the basics.

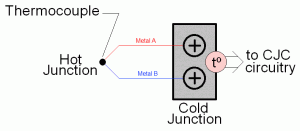

A TC is comprised of two dissimilar metals that are welded together into a junction on one end (the temperature sensing end) and individually on the other end where the TC wire connects to a suitable measuring instrument. The junction on the temperature measuring end is commonly called the hot junction, while the instrument end is called the cold junction. TC-based temperature measurement relies upon the so-called Seebeck Affect that predicts a current flow in the two metals as long as the hot and cold junctions are at different temperatures, and the magnitude and direction of this current flow is a function of the temperature difference between the junctions. An accurate temperature measurement is made by measuring both the voltage produced by the hot junction and the temperature at the cold junction. Cold junction temperature measurement is known as cold junction compensation (or, CJC.) Since the cold junction (the instrument end) is not exposed to the temperature extremes of the hot junction, CJC is accomplished with a temperature sensing device that has a comparatively narrow range. This CJC temperature range is almost always speced by the instrument, and usually falls between 0 and 70ºC. Accurate temperature measurements at the hot junction are possible only as long as the cold junction temperature remains within the CJC range spec. Back to our application.

A TC is comprised of two dissimilar metals that are welded together into a junction on one end (the temperature sensing end) and individually on the other end where the TC wire connects to a suitable measuring instrument. The junction on the temperature measuring end is commonly called the hot junction, while the instrument end is called the cold junction. TC-based temperature measurement relies upon the so-called Seebeck Affect that predicts a current flow in the two metals as long as the hot and cold junctions are at different temperatures, and the magnitude and direction of this current flow is a function of the temperature difference between the junctions. An accurate temperature measurement is made by measuring both the voltage produced by the hot junction and the temperature at the cold junction. Cold junction temperature measurement is known as cold junction compensation (or, CJC.) Since the cold junction (the instrument end) is not exposed to the temperature extremes of the hot junction, CJC is accomplished with a temperature sensing device that has a comparatively narrow range. This CJC temperature range is almost always speced by the instrument, and usually falls between 0 and 70ºC. Accurate temperature measurements at the hot junction are possible only as long as the cold junction temperature remains within the CJC range spec. Back to our application.

On the destination end of the trip, data uploaded from the logger showed that temperature readings were fine at the very beginning and at the very end of the flight. In between, things went a little nuts. We immediately suspected a problem either with the logger’s battery or CJC sensor if the cargo hold of the aircraft was neither pressurized or heated. Further investigation revealed that the CJC range of the logger is not a published specification, nor is the battery speced for operating temperature and ambient pressure. We turned to the manufacturer for this information.

While we waited for a response the customer had queried FedEx for details related to the cargo hold environment on typical flights and received this response:

On board FedEx Express aircraft, temperatures vary depending on the type of aircraft, the location of each cargo compartment and the package location within each compartment, the length of flight, and the cruising altitude. For general reference, temperatures aboard most wide-body aircraft main cargo compartments vary between 65 F (18 C) and 90 F (32 C). Packages positioned in the bulk department, next to the aircraft’s outer structure, might be exposed to temperatures as low as 0 °F (-18 °C) during flight. Air pressures on FedEx aircraft vary from as low as 8.3 psi at cruise altitude to as much as 14.7 psi on the ground.

Information received from the manufacturer revealed the battery operating range to be -55 to 85°C, and the fact that it is hermetically sealed. This update effectively eliminated the battery as a possible cause of the problem. However, the CJC measurement range of the logger was confirmed to be 0 to 70°C. Since the logger was already in a chilled environment (close to frozen samples) we suspected that this, in combination with the cold cargo hold, exposed the logger to an ambient temperature lower than its 0 °C specification. Since accurate cold junction temperature measurements are a prerequisite for accurate hot junction measurements, the logger failed while this condition existed.

Our customer is investigating ways to better insulate the logger from cold ambient temperatures and is confident that she can find a solution.

View Cart

View Cart sales@dataq.com

sales@dataq.com 330-668-1444

330-668-1444