Additional Reading:

4-20 mA Shunt Resistor and Current Loop Data Acquisition Products

It seems that at least one 4-20 mA (milliamp) measurement is required by our typical customer, and the way to do it is a constant source of confusion for many. So I thought I’d zero in on the various 4-20 mA current loop configurations and elaborate on the specifics that you need to know to make a successful measurement. The following discussion is ordered from the most to least common configuration, and I hope to cover all those that I have encountered in customer applications. If yours isn’t included, please use the comments section to fill me in.

4-20 mA Current Loop Basics

Sensors or other devices with a 4-20 mA current loop output are extremely common in industrial measurement and control applications. They are easy to deploy, have wide power supply requirements, generate a low noise output, and can be transmitted without loss over great distances. We encounter them all the time in both process control and basic measurement data logger and data acquisition applications.

The idea behind 4-20 mA current loop operation is that the sensor draws current from its power source in direct proportion to the mechanical property it measures. Take the example of a 100 psi sensor with a current loop output. With 0 psi applied, the sensor draws 4 mA from its power source. With 100 psi applied the sensor draws 20 mA. At 50 psi the sensor draws 12 mA and so on. The relationship of mechanical property measurement to current output is almost always linear, allowing the resulting current loop data to be scaled with a simple mx+b formula to reveal more useful measurements scaled into engineering units.

How you actually measure the 4-20 mA current loop signal is a function of the sensor’s architecture and the capabilities of the instrument you’ll use for the measurement.

Terminology

So that my discussion translates well across the various kinds of 4-20 mA current loop configurations, I’ve opted to standardize the terminology I use to describe each. Here’s an overview:

“E” (dc excitation)

Most configurations that follow will show a DC voltage excitation source that I denote as “E”. Many who use current loop sensors for the first time are surprised to learn that they need to supply this excitation source. Nonetheless, unless the sensor is self-powered (i.e. AC line powered) an external dc source is required. The good news is that this can sometimes be supplied by the instrument, and the range of acceptable values is usually very wide, typically 10-24 V dc.

“R” (shunt resistor)

Here’s a bit of trivia for you: No instruments measure current directly. They all do it indirectly by measuring the voltage dropped across a resistor of known value, and then they use Ohm’s Law to calculate actual current. The resistor is referred to as a “shunt”, is absolutely required to make a current measurement, and is either supplied externally to, or built into the measuring instrument. For clarity, I assume that it’s supplied externally.

“i” (current loop value ranging from 4-20 mA)

This is the 4-20 mA current signal generated by the sensor. Note that some sensors may draw 0-20 mA and even other values, but the vast majority of them use the 4-20 mA convention.

“v” (shunt voltage that’s proportional to current)

This is the voltage drop across the shunt that is actually measured by the instrument. Since our industry has standardized on a shunt value of 250 Ohms, “v” will range between 1 and 5 volts for a 4-20 mA current loop signal (v=i * resistance). Note that shunt resistor value is arbitrary as long as it’s known. You also need to ensure that it doesn’t burden the loop, so lower values are better than higher. Yes, I mean lower. Remember that we’re working with current, not voltage, so the rules are inverted. Just as infinitely-high resistor loads work well for a voltage source, you can take the load all the way to zero Ohms for a current source without consequence.

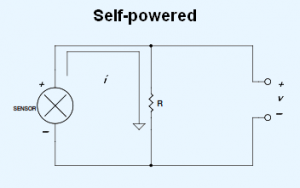

Self-powered Sensors

I promised to order these configurations from most to least common, and the self-powered sensor just noses out the first runner up. Self-powered sensors are those that, well, power themselves. The sensor may have an integral ac power supply, thereby negating the need for an external DC power source. Or it may not be a sensor at all. It could be an output from a PLC or other source that is internally powered.

I promised to order these configurations from most to least common, and the self-powered sensor just noses out the first runner up. Self-powered sensors are those that, well, power themselves. The sensor may have an integral ac power supply, thereby negating the need for an external DC power source. Or it may not be a sensor at all. It could be an output from a PLC or other source that is internally powered.

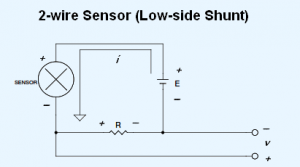

2-wire Sensors (Low-side Shunt)

Okay, this can get confusing for first-time 4-20 mA current loop users. Yes, it is possible to both power the sensor and measure the current it draws over the same two wires. In the 2-wire examples shown here, only two wires connect the sensor to its power supply, and the sensor draws current from it in direct proportion to the mechanical property that it measures. As current changes, the voltage developed across resistor R will change, thus providing a signal that’s suitable to connect to a measuring instrument like a data logger or data acquisition system.

Okay, this can get confusing for first-time 4-20 mA current loop users. Yes, it is possible to both power the sensor and measure the current it draws over the same two wires. In the 2-wire examples shown here, only two wires connect the sensor to its power supply, and the sensor draws current from it in direct proportion to the mechanical property that it measures. As current changes, the voltage developed across resistor R will change, thus providing a signal that’s suitable to connect to a measuring instrument like a data logger or data acquisition system.

In most situations, care should be taken to place the resistor in the low-side of the loop as shown here, as opposed to the high-side. Doing so will allow non-isolated instruments to make the measurement. In the next section, I’ll deal with a high-side shunt placement and discuss these cautions in more detail.

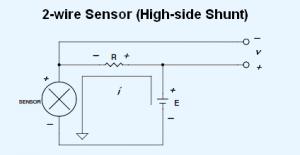

2-wire Sensors (High-side Shunt)

This configuration is almost exactly like the low-side, 2-wire approach, but it places the shunt resistor in the high-side of the loop. Note that while the voltage across the resistor is proportional to the current drawn by the sensor (just like the low-side approach), there is also a common mode voltage (CMV) present on either side to ground. On one side to ground the CMV is equal to the supply voltage. On the other side to ground it’s equal to the supply voltage, less the voltage dropped by the resistor (v). The presence of the CMVs places conditions on the instrument that you use to measure v. Specially, the instrument needs to have an isolated front end so it can float to the level of the CMV and still successfully make the measurement. Try this with a non-isolated, single-ended instrument and you will short-circuit the sensor to ground. A non-isolated differential instrument will either saturate or provide erroneous results.

This configuration is almost exactly like the low-side, 2-wire approach, but it places the shunt resistor in the high-side of the loop. Note that while the voltage across the resistor is proportional to the current drawn by the sensor (just like the low-side approach), there is also a common mode voltage (CMV) present on either side to ground. On one side to ground the CMV is equal to the supply voltage. On the other side to ground it’s equal to the supply voltage, less the voltage dropped by the resistor (v). The presence of the CMVs places conditions on the instrument that you use to measure v. Specially, the instrument needs to have an isolated front end so it can float to the level of the CMV and still successfully make the measurement. Try this with a non-isolated, single-ended instrument and you will short-circuit the sensor to ground. A non-isolated differential instrument will either saturate or provide erroneous results.

High common-mode 4-20 mA Current Loop Data Logger DI-2108P

Isolated 4-20 mA Current Loop Data Logger DI-4718, DI-2008, DI-245 and DI-808

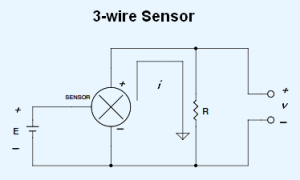

3-wire Sensors

Three-wire sensors with a process current output have a separate wire for ground, signal (4-20 mA), and the power supply. This configuration is the easiest for current loop beginners to grasp, one input for power and a second for the current loop with a common ground. The primary advantage of a 3-wire sensor over its 2-wire counterpart is its ability to drive higher resistive loads. Resistors drop voltage for any given current in direct proportion to their resistance value. Holding current constant, higher resistances drop more voltage. Turning back to the 2-wire sensor and holding current constant, as the shunt resistance increases the voltage drop across it also increases. You might reach a point where the voltage dropped by the shunt lowers the voltage drop across the sensor below the minimum required for it to operate properly.

Three-wire sensors with a process current output have a separate wire for ground, signal (4-20 mA), and the power supply. This configuration is the easiest for current loop beginners to grasp, one input for power and a second for the current loop with a common ground. The primary advantage of a 3-wire sensor over its 2-wire counterpart is its ability to drive higher resistive loads. Resistors drop voltage for any given current in direct proportion to their resistance value. Holding current constant, higher resistances drop more voltage. Turning back to the 2-wire sensor and holding current constant, as the shunt resistance increases the voltage drop across it also increases. You might reach a point where the voltage dropped by the shunt lowers the voltage drop across the sensor below the minimum required for it to operate properly.

We had a customer whose 2-wire current loop measurements functioned beautifully until loop current reached about 18 mA, at which point everything went haywire. Upon close examination, we determined that the supply voltage she used was too low by at least 0.56-V. She needed 2 mA more measurement to reach full scale, which translates to 0.56 V with her 250-Ohm resistor. The solution was to use a higher voltage power supply to ensure that the voltage drop across the sensor stayed above the minimum level. She could have also used a 3-wire sensor, which ensures that the voltage applied to the sensor is independent of shunt resistor voltage drop.

Watch Your Grounds (or use an isolated instrument)

Contrary to what many believe (and have been erroneously taught in school), grounds are almost never the same in industrial settings, exactly where most 4-20 mA current loop sensors are used. Two or more grounds that are the same means that they are at the same potential. If so, a measurement between the grounds of the various field sensors and the instrument using a digital volt meter (DVM) on both its DC and AC settings will show zero volts, or very close to it. In reality, you’ll measure at least several volts, and I’ve seen as much as 75 Volts. When grounds that are not at the same potential are tied together (which you need to do to make a measurement), current flows through them, creating several possible measurement outcomes for non-isolated instruments:

- The measurement is noisy.

- The measurement is inaccurate.

- You irreparably damage the instrument.

- You saturate the instrument (it’s not damaged, but you can’t make a successful measurement, either.)

To remedy these problems requires the following:

- Use an isolated instrument for your 4-20 mA current loop measurements. This single decision allows you to ignore all other grounding issues in exchange for successful measurements in any situation. If you don’t have an isolated instrument, read on…

- Ensure that the loop power source is isolated. This means that its output ground (the one connected to the sensor) is not tied to its input ground (the one that connects to AC line power.) An isolated power source means that the output ground can be tied to another ground (like a non-isolated instrument) without consequence.

- If using self-powered sensors, ensure that the low-side of the loop is isolated from its power source.

- If using sensors that require an external dc power source, ensure that the shunt resistor is placed in the low side of the loop (see “2-wire Sensors (Low-side Shunt)” above.)

- If you lack control over the power sources and determine that they are not isolated, then your only option is to power ALL devices (power supplies, self-powered sensors, the instrument, and its connected PC) from exactly the same power outlet. Don’t make the mistake of using outlets that are close to each other. If you run out of receptacles on a single outlet, then use a power strip.

Again, it’s worth repeating that all of the cautions associated with proper grounding disappear if an isolated instrument is used to make the measurement.

Isolated 4-20 mA Current Loop Data Logger DI-4718, DI-2008, DI-245 and DI-808

Sensors with 4-20 mA outputs are encountered in all disciplines and in many configurations. Contact us with any questions that arise in your unique situation.

View Cart

View Cart sales@dataq.com

sales@dataq.com 330-668-1444

330-668-1444

35 Comments

ASGAR ALI

i want to know differents type of instrumnet

Mike Maher

Thanks for the good article!

James Stevens

Hello ,

Just got our first 2 new units. They look great thanks.

I am trying to figure out a simple method for customers to set up the logger.

If we set the logger up 0-100% = 4-20 mA for all flows.

The customer can then copy into a spreadsheet and do a converison.

We constantly get calls on how to set it up and wonder how we can eliminate setting up the meter and the logger to match.

Any ideas would be welcome. The neg flow here is obviously when the current was off.

James

DaqGuy

Nothing prevents you from deploying the logger with its default 0-100% scaling for a 4-20 mA input. However, since scaling has to be done somewhere, you’d need to multiply acquired percentages by the full scale range of the sensor to yield meaningful units inside Excel.

Boiler Maker

Well written article.

I do, however, have an issue with the statement “No instruments measure current directly.” An analog panel meter without a shunt resistor does exactly that. It takes a current and its resultant magnetic field and deflects a pointer that is read on a calibrated scale.

Thanks,

Dale

DiptiPrakash Palai

How it has been come up with an idea to use specifically 4-20 milliamp.

Igor

hi! thanks for the article.

I got a question.

You recommend to take the shunt resistor lower. But this resistor is connected parallel to the power supply. If it is too low, can it damage the power supply.

If to consider the schematic #1 (“self-powered”). There is current “i” produced by the sensor. But the overall current flowing through the resistor will also include the (Vsupply/Rshunt)?

DaqGuy

In no configuration is the resistor in parallel with the power supply. It is always in series with the sensor and power supply, so its resistance can decrease to zero without consequence.

In answering your second question, the self-powered configuration removes the power supply from consideration.

Viplaw

Hi Igor. I think as it’s appear by it’s name “Self-Powered”, i think it doesn’t needs any external power supply, it gives output by it’s measured mechanical power … so the resistor is in it’s series with sensor . and the poles u see in figure are output point of signal .. not a input power . As i think .

Siziwe

2wire 3wire and 4wire loops

Nick

Hi why not use 500ohms instead of 250? If you use 500 in 20mA you get 10V in this way don’t you have better resolution of the measurement? Thank you

DaqGuy

You can do that, but as the article mentions, larger shunt resistances burden the loop more. Ideally the shunt value should be zero Ohms, but that isn’t practical. As shunt resistance increases voltage drop across it increases in direct proportion to loop burden. Eventually you reach a point where the loop fails to function.

Viplaw

Hello Nick , as you said you will get 10V if u apply 500 Ohms resistance, but maximum ADC system measures 5V as max input , so the getting 10V from sensors output is just a useless because we will have to decrease that .

Gideon Guy

Hello,

I’d like to measure the current coming out of a battery. I can place a small series resistor (say, 1ohm) at the negative port of the battery and measure the voltage across it with my DI-149, but the voltage is quite low (0.1-0.5 volt), and the measurement resolution of your device is not sufficient. Any ideas on how to better measure this without dropping too much voltage on (A bigger) resistor?

Thanks,

-Gideon

DaqGuy

Only one way: Add an amplifier either inside our outside the instrument. If you want the instrument to handle it consider model DI-245:

http://www.dataq.com/products/di-245/

Gaurav

We want to use amplitude collected at 4.8 Khz (frequency) using a GSM module – via GPRS to a cloud or a server. similarly we want to do for 38 Khz as well.

any solution that we can deploy. We propose to use a Pizeo crystal in a SS encasement.

Manoj

Nice Information!

How to make accurate reading at receiver side in noise medium.

Joe Dunford

Excellent article, well written and comprehensive, well prioritized. Obviously the product of an orderly mind. Thanks!

Aakash Garg

How can I interface 2 wire sensor which give 1-5 volt drop against 4 – 20 mA current loop?

DaqGuy

If your sensor has a 1-5 V output the manufacturer has built a shunt resistor into the device to provide a voltage output. Therefore, no external shunt resistor is necessary.

Joshua Alegbe

please how do I use my digital multimeter DT9205 to carry out 4-20mA to simulate a loop powered sensor for its calibration. The sensors are humitter and barometer.

Pls treat urgent.

walt gerhold

4-20 madc for div2 electrical can I use zener diode in loop

Qamar

Thank you very much for sharing the knowledge with others. You have articulated the concepts very nicely.

I have a question for you… The question is infact an observation that i have been facing for last 2,3 years.

Spikes are being observed in a 2 wire looped power level transmitter installed on vessel in a facility where i am working.

I have done all possible checks, configuration, re-configurations to address the issue. And luckily, situation has gone quite acceptable now. Only one spike is observed in its reading. As per my understanding, this too is in fact an actual spike due to process disturbance.

but i intend to suppress this spike as well.

AND FOR NOW

I am intending to install an inductor in its loop to suppress this sudden change in mA values.

How is the idea and what are your inputs regarding this way forward.

PETER TRUNCALE

I HAVE A DEW POINT TRANSMITTER WITH A 4-20mA ANALOG OUTPUT.

I WANT TO MEASURE 0-20-LBS/SCF.

THE SCALING IS IN DEG.C SO BY DOING A CONVERSION 20 LBS. = -29.1 DEG. C.

I SET THE RANGE AS -100 = 0 LBS., AND -29.1 DEG. C =-20 LBS.

MY QUESTION IS THIS.,

IS THE RESOLUTION BETTER SET AT -100 TO -29.1.,

OR -65 TO -29.1

Somdutta Chanda

Could you please elaborate the difference between low side shunt and high side shunt? It would be better to represent with the schematic of ground coupling and why exactly low side shunt is better. Thanks!

Daqhelper

Somdutta,

When placed on the low side of the circuit, you’re measuring the voltage drop across the shunt resistor. On the high side, you’re measuring the voltage drop across the shunt, in addition to the loop supply voltage.

As stated in the post:

“On one side to ground the CMV is equal to the supply voltage. On the other side to ground it’s equal to the supply voltage, less the voltage dropped by the resistor (v). The presence of the CMVs places conditions on the instrument that you use to measure v. Specially, the instrument needs to have an isolated front end so it can float to the level of the CMV and still successfully make the measurement. Try this with a non-isolated, single-ended instrument and you will short-circuit the sensor to ground. A non-isolated differential instrument will either saturate or provide erroneous results.”

Regards,

Shawn MacDonald

Application Engineer

DATAQ Instruments Inc.

Gary Thalman

I’m planning to use the DI-1110 to measure the individual batteries on a golf cart. (total of 6 batteries). I would also like to measure the current draw from the batteries. I can do this by adding a 500amp 75mV shunt, but the resolution is not very good. With a 4.5mV accuracy, it looks like the resolution will be in the 33 amp range. I’m hopefull that the 1-20 mA current loop configuration would work for this. Can you comment on this?

Daqhelper

Gary,

A product like the DI-2108-P, with built-in programmable gain, would be a better choice.

The DI-2108-P features programmable full-scale measurement ranges of ±2.5, ±5, ±10, 0-5, 0-10 Volts, with up to 16-bit resolution (sample rate dependent).

Regards,

Shawn MacDonald

Application Engineer

DATAQ instruments Inc.

Simon Yap

Dear sir

How choose a right 24vdx power supply to power 5 nos of 4-20ma transmitter.

Regards

Simon

Daqhelper

Hello Simon,

Sorry for the late reply.

A Google search should yield good results. You might consult with the transmitter manufacturer.

Here’s an example of the type of power supply you’re looking for:

https://api-usa.com/loop-power-supplies.php

Regards,

Shawn MacDonald

Application Engineer

DATAQ Instruments Inc.

Polycab India Limite

The loop power supply voltage must always be higher than the sum of all the voltage drops in the circuit, including the field wiring voltage drop. Otherwise, it will create a major problem like a short-circuit.

Vaibhav

Dear Sir,

I want to use 6 no.s of loop powered (4 to 20 mA) flow sensors with NI 9203 (Single ended Analog Current Input module).

Request you to please suggest the right connections for the same.

Regards,

Vaibhav

Daqhelper

Hello Vaibhav,

I’m sorry, the NI 9203 is not our product. Please contact NI.

You’ll find our selection of 4-20mA data loggers at:

https://www.dataq.com/data-logger/4-20ma-process-current/

Regards,

Shawn MacDonald

Application Engineer

DATAQ Instruments Inc.

electricians near me

Thaks for sharing.

electricians near me

Thanks for sharing.