Thermocouple Measurements Profile Cement Curing Characteristics of Prosthetic Implants

Introduction

It's obvious that prosthetic implants have changed the lives of countless thousands for the better. Knee, hip, and shoulder replacements are common surgeries today, substituting diseased or damaged joints with synthetic materials that allay pain and simultaneously restore mobility and quality of life. Not as obvious is the technology at work behind the scene that makes these life-changing surgeries possible. This application note will examine one small aspect of this technology and relate how DATAQ Instruments' hardware and software products were used to help improve joint replacement know-how and success rates.

Background

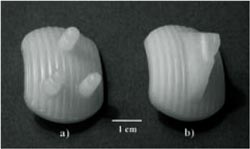

Our customer, a surgeon experienced in joint replacements wanted an answer to a question: Could the cement that is used to fix a prosthetic socket to bone in shoulder replacement surgeries ultimately lead to bone damage and early prosthetic failure? The question is logical when you consider that the cement, called PMMA (Polymethylmethacrylate), is like an epoxy that is supplied in two parts: a liquid activator, and powdered PMMA. Further like an epoxy, when the two parts are mixed heat is released. Could the heat generated from this chemical reaction be intense enough, and last long enough to actually damage surrounding bone and lead to premature joint failure? To answer this question the surgeon decided to run a series of tests on a cadaver under various conditions. Specifically he would run profiles on the two styles of prosthetic shoulder sockets in use today, pegged and keeled designs (Figure 1).

Figure 1 — The two primary types of glenoid prostheses used for shoulder replacements are the pegged (a) and keeled (b) types. Since the volume of PMMA required to fix the pegged socket is less than the keeled version, and the quantity of generated heat is directly proportional to the volume of PMMA used, the amount of heat released would vary as a function of the socket style that is employed. In either case, it was determined to be essential to limit the magnitude of released heat to 40°C, or the dwell time in excess of that temperature.

Instrumentation

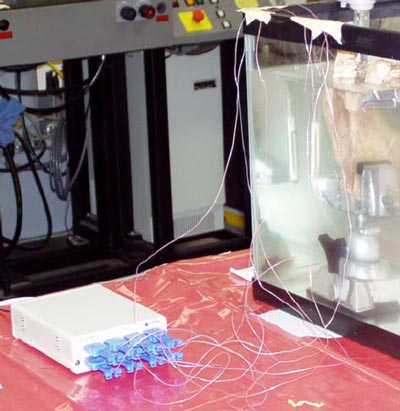

DATAQ Instruments' model DI-1000TC-8, eight-channel thermocouple temperature logger was chosen for the test (Figure 2). Especially critical for the low noise measurements required by the application is the unit's fully isolated design. This approach eliminates the noise-producing affects of common mode voltages that cause poor measurement results. The DI-1000TC was connected to the USB port of a personal computer running WinDaq data acquisition and playback software, which was used as the primary vehicle for monitoring the test in real time and for analyzing results afterward.

Figure 2 — The model DI-1000TC-8 used in the study is shown here positioned near the water bath.

Procedure

- The scapula (shoulder area with socket) of a cadaver was removed and immersed in a water bath that is maintained at body temperature (approximately 37°C). See Figures 3A and 3B.

Figure 3A — The shaded part of this diagram shows the anatomical location of the scapula that was removed from a cadaver for this study.

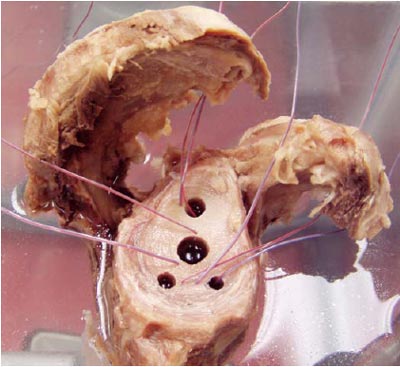

Figure 3B — The excised scapula shown here immersed in a water bath that is maintained at body temperature (approximately 37ºC). - The socket area of the scapula was machined to a geometry that would allow it to receive the prosthetic socket, either the keeled or pegged version. In addition, very small diameter holes were drilled in the scapula at strategic locations spaced several millimeters apart. These holes received fine, T-type thermocouple wire that ultimately connected to the DI-1000TC. Multiple locations were chosen so temperatures could be measured not only at the cement/prosthesis interface, but also at defined distances from this location to measure the affect of heat conduction through the bone. Figures 4A and 4B show scapulas that were machined for pegged and keeled prostheses respectively.

Figure 4A — The scapula shown here has been machined to accept a pegged prosthesis and fine-wire T-type thermocouples.

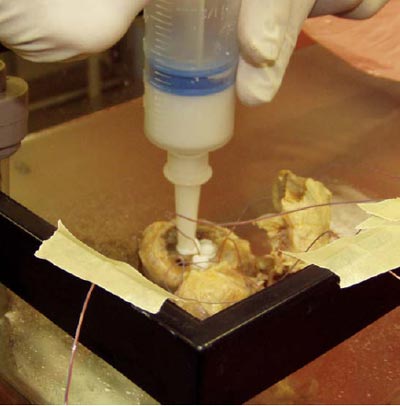

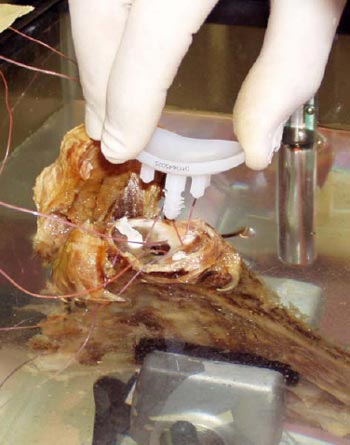

Figure 4B — The scapula shown here has been machined to accept a keeled prosthesis and fine-wire T-type thermocouples. - Holes used to secure the prosthetic socket were filled with PMMA cement, and the prosthesis is mounted (see Figures 5A and 5B). Separate tests are run with keeled and pegged versions.

Figure 5A — The holes that will receive the prosthesis are filled with PMMA cement.

Figure 5B — The prosthesis, in this case a pegged type, is fitted to the scapula. - Over a period of approximately 12 minutes, the average PMMA cure time, temperature recordings were made at the following locations:

- Directly at the bone/cement interface.

- Spaced several millimeters from the bone/cement interface.

- The water bath.

See Figures 6A and 6B, generated by WinDaq software and the DI-1000TC.

Figure 6A — A temperature recording of a pegged implant. All channel strips have been calibrated in ºC. The upper limit is 80ºC, while the middle grid value is 40ºC. The circled area indicates where the temperature exceeded 40ºC.

Figure 6B — A temperature recording of a keeled implant. All channel strips have been calibrated in ºC. The upper limit is 80ºC, while the middle grid value is 40ºC. Circled areas indicate where the temperature exceeded 40ºC.

Results and Conclusions

Several recordings were made of tests using both keeled and pegged versions of the prosthesis. Although the PMMA curing temperature for both exceeded the implied 40°C limit, the keeled version exhibited the greatest excursions in temperature for the longest period of time (Figure 7). This was expected based upon the inherent requirement for more PMMA cement to fix the keeled as opposed to the pegged prosthesis. Further study is required to determine the extent to which bone can survive the high curing temperatures of PMMA cement, and the length of time of that exposure. However, the study accomplished it primary objective, which was to quantify, profile, and document the range of temperatures to which bone is subjected during a typical shoulder replacement procedure.

Figure 7 — Comparative temperature profiles at the bone/cement interface of the pegged and keeled prostheses.

As expected, the keeled type achieves a maximum temperature nearly twice as hot as the pegged type (80 versus 46ºC) and stays above 40ºC for 340 versus 101 seconds.

Additional Reading:

Ambient Temp Affects Thermocouple Measurement Accuracy

Maximum Thermocouple Wire Length

View Cart

View Cart sales@dataq.com

sales@dataq.com 330-668-1444

330-668-1444